PTI Industries Help Aerospace Manufacturers Meet Increasing Demand

Our previous blog post on the aerospace industry focused on the critical safety and quality of aircraft components. PTI helps keep aircraft in safe flying condition by providing multiple manufacturing services with our hundreds of special process approvals from over forty OEMs, and certifications from the FAA, EASA, and NADCAP.

Our previous blog post on the aerospace industry focused on the critical safety and quality of aircraft components. PTI helps keep aircraft in safe flying condition by providing multiple manufacturing services with our hundreds of special process approvals from over forty OEMs, and certifications from the FAA, EASA, and NADCAP.

This update focuses on the high demand for new commercial aircraft. A worldwide commercial aircraft demand presents new challenges for both airframe and engine manufacturers alike. The global aerospace industry faces the challenge of improving productivity and responding to ever increasing government regulations.

The expected growth rate is largely driven by an increased demand for new low-cost carriers from emerging economies and their growing middle class. Projected growth estimates from 2015 through 2033 total over 35,000 new aircraft, with an average of eight and a half planes and seventeen aircraft engines a day.

These opportunities mean aerospace manufacturers need qualified suppliers and service providers. The required scope and knowledge to invest in and perform advanced manufacturing services is part of the ongoing challenge aerospace companies must face as they redouble efforts to reduce costs.

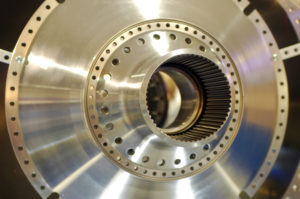

PTI helps to alleviate this challenge by reducing lead times with ten special processes performed in-house, at one location, including:

- Adhesive Bonding

- Dry Film Lubrication

- Magnesium Coatings

- Non-Destructive Testing

- Pressure Testing

- Passivation

- Precision Cleaning & Cleanliness Testing

- Repair Services

- Shot Peen

World travel is anticipated to continue growing over the next twenty years by five percent per year as it has since 1980. The numbers of annual flight passengers will rise from a fifth of the population in emerging markets to two thirds, with global passenger numbers doubling to over six billion.

As the market for worldwide commercial aircraft grows, PTI’s special process technology has the advanced techniques needed to help meet the new volume challenge for aerospace components.

Leave a Reply

Want to join the discussion?Feel free to contribute!