Specialized In-House Solution For Precision Cleaning of Gas Turbine

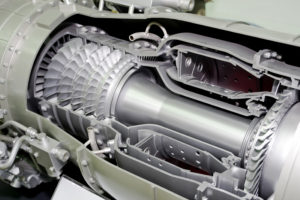

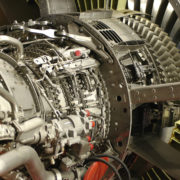

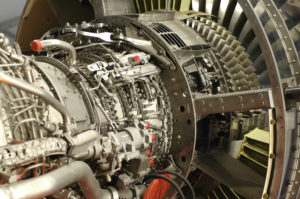

As part of their new project, a customer came in with a very complex part. The part is for a large domestic gas turbine manufacturer, and its internal cleanliness is paramount. Any debris left in the part could find its way into the turbine, wreaking havoc with the blades and the turbine’s performance.

As part of their new project, a customer came in with a very complex part. The part is for a large domestic gas turbine manufacturer, and its internal cleanliness is paramount. Any debris left in the part could find its way into the turbine, wreaking havoc with the blades and the turbine’s performance.

There are many methods to precision clean parts, yet this part posed unique challenges. The precision cleaning process includes an emphasis on removing soil and debris in relation to the design of the parts, and is often performed on precision parts that are manufactured with infinitesimal precision or complex dimensions. This particular job needed a specialized approach due to its intricate design.

To comprehend its precision cleaning requirements, it’s necessary understand the complex design. The part begins as a massive 850-pound block of metal that undergoes machining of irregularly shaped grooves that act as passageways for the fuel to flow to the fuel nozzles. Once the intricate grooves are completed, thin metal strips are welded over the grooves to create the fuel passageways.

The final manufacturing step involves machining holes into both sides of the part. At this point, the machining creates chips that break through and get into the passageways. Because the passageways are difficult to access, the chips are impossible to see and efficiently remove.

Guided by our state-of-the-art, multi-directional articulating borescopes, we used specialized tools custom designed and built in-house to access the passageways. The borescopes we use have both still photo and video recording capabilities, allowing us to not only locate and see the debris, but to also view how to maneuver the specialized tools. We were able to clear all the debris out as well as record the entire removal process, proving beyond a doubt that the chips are completely removed. To ensure this, we provided verification through video recordings of both before and after conditions.

As gas turbine engines grow more sophisticated in both mechanical design and power capacity, it becomes increasingly important to resolve precision cleaning challenges with the highest accuracy. Many critical components require highly sensitive procedures to achieve efficient and safe performance, and to attain long-term and consistent service.

PTI Industries performs precision cleaning and cleanliness testing using a wide range of precision cleaning methods and equipment that include ultrasonic, CO2 snowgun, vapor degreasing, media blasting, aqueous immersion, turbulent flushing, and high-pressure spray. Our list of certifications and specialized process approvals are designed to comply with industry specifications. We examine each part’s precision cleaning needs to propose and devise the best industry-approved solution.

Contact Us at 860-698-9266 to discuss your precision cleaning challenge.

In our previous post we discussed the serious, even catastrophic consequences contamination can cause. Medical device manufacturers –from small machine shops to large corporations – need to establish protocols that enable them to consistently deliver clean components and meet regulatory standards.

In our previous post we discussed the serious, even catastrophic consequences contamination can cause. Medical device manufacturers –from small machine shops to large corporations – need to establish protocols that enable them to consistently deliver clean components and meet regulatory standards.

PTI Industries continues to offer special processes for critical aerospace components, helping the aerospace industry meet an increased demand while adhering to stringent quality standards. Strict adherence to NADCAP, FAA, and EASA certifications and accreditations ensures your parts performance, reliability, and safety.

PTI Industries continues to offer special processes for critical aerospace components, helping the aerospace industry meet an increased demand while adhering to stringent quality standards. Strict adherence to NADCAP, FAA, and EASA certifications and accreditations ensures your parts performance, reliability, and safety.

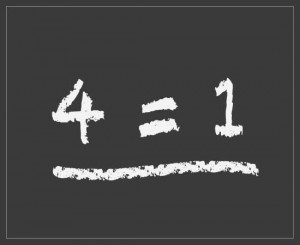

In a previous post we spoke about streamlining your special processes to improve your bottom line. Now we’ll take a look at how one part would move through our multi-process shop. Four processes can equal one when a part has four sequential special processes done in one shop on one purchase order. To illustrate this, let’s look at a section of the value stream map for a Locking Nut that mates up to an LPT Shaft, which ultimately ends up in a jet engine.

In a previous post we spoke about streamlining your special processes to improve your bottom line. Now we’ll take a look at how one part would move through our multi-process shop. Four processes can equal one when a part has four sequential special processes done in one shop on one purchase order. To illustrate this, let’s look at a section of the value stream map for a Locking Nut that mates up to an LPT Shaft, which ultimately ends up in a jet engine.